8 March, 2021

Potato Products and the Importance of the Raw Material

The very foundation to produce high-quality potato products is to use a raw material that matches the standard criteria for the final product, regarding size, dry matter (DM), starch and reducing sugars. However, seasonal changes and other uncontrollable factors will affect the potato characteristics over time. You will therefore need a flexible processing line to cope with the variations. In this text we will explain how you as a producer can manage these fluctuations and maintain a high quality in the final product.

A Typical Potato

The potato is a living material, and the product characteristics changes over time since it is genetically programmed to survive during the seasons and to regenerate. A potato consists of approx.

- 79 % Water.

- 16 % Starch.

- 2 % Protein.

- 1 % Raw fiber.

- 0,5 % Fat.

- Rest. Vitamins, minerals, reducing sugar etc.

External Quality

When it comes to snack or frozen potato product processing, differences in the external quality will be what firstly determine which product the potato is best suited for, to reduce waste and optimize the quality of the product. The size is particularly of importance and following sizes are recommended after product type:

- When producing Potato Chips, it is more favorable to have round tubers with a size range of 40 – 60 mm.

- When producing French Fries, it is more favorable to have long and oval, or long tubers, with a size of ≥ 50 mm.

Internal Quality

Differences in the internal quality is, compared to the external quality, more important when it comes to the quality of the final product. If you do not have the right internal characteristics you will not be able to produce high quality potato products. However, there are a few internal ingredients of the dry matter that are more important than others.

Dry Matter (DM)

The definition of DM is the mass fraction in the potato that remains after the water fraction has been removed and it is presented in percent (%). The DM is the most important part to be aware of when processing potatoes to snacks, since this is what remains after frying – the actual product.

An even DM content in the potatoes is favorable to create an optimal frying of each individual potato slice. If the DM is even in all potatoes, the frying temperature and time will be easier to set. The result will be evenly fried potato slices and in other words, perfectly fried potato chips.

Potatoes with uneven DM must be fried according to the part with the highest water content to avoid wet parts in the final product. The potato slices with the higher DM will then be over-fried, brown and the fat will be sucked in permanently, which cannot be removed.

If the potato has a high DM, yield will be higher, energy costs lower and capacity in the fryer will be higher, which will maintain a high oil quality, and will normally also result in a lower fat content in the final product. Following DM are recommended per product type:

- For Potato Chips it is recommended to have a DM between 21 – 26 % and will result in crispy chips with a lower fat-unit.

- For French Fries it is required to have a DM between 20 – 24 % and will result in crispy and firm French Fries with a lower fat unit.

Starch and reducing sugars are both included in the DM and can be removed from the potato by mechanical treatment in the processing line.

Starch

The reason why starch exists in some raw materials, is the in-built mechanism to survive. When the raw material gets cold and has used its’ supply of reducing sugars, the available starch can be converted into glucose to get necessary energy to survive. It is therefore important to handle and store potatoes in the right environment, so that you can maintain good potato characteristics before processing.

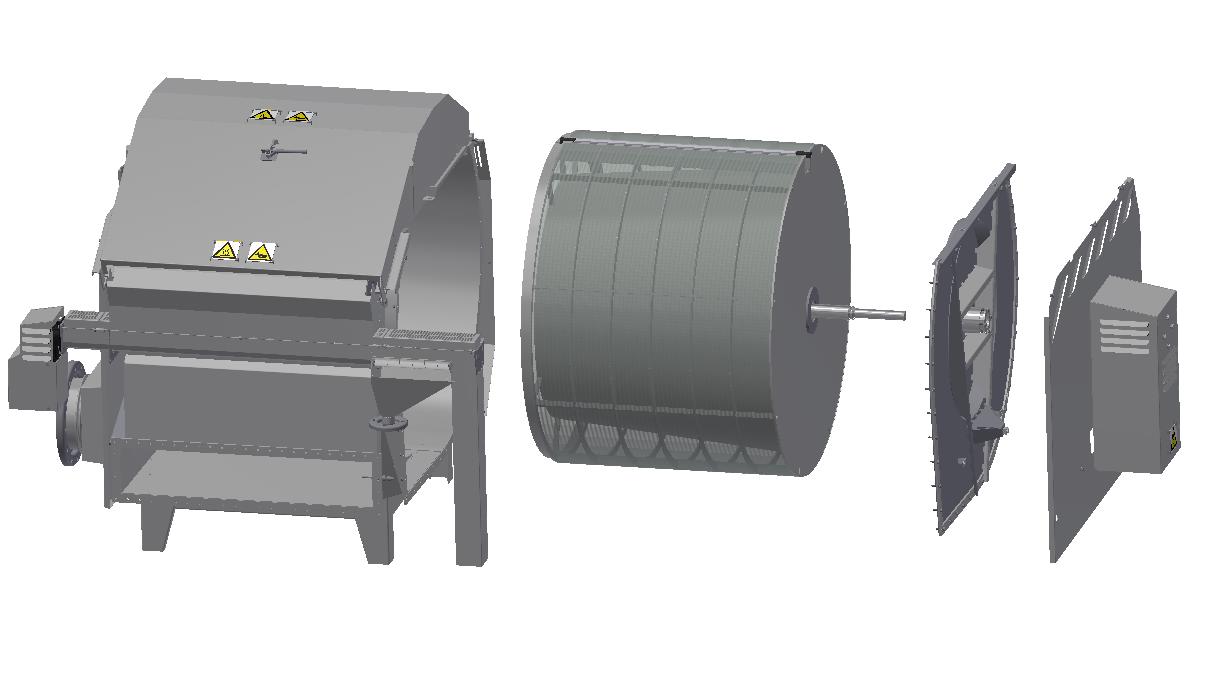

In the French Fry industry, modified starch can be added to some products to create a better texture and crisp in the product. But, when having starch as a natural part of the raw material, too much of it will result in a big amount of free surface starch when cutting and slicing. When producing potato chips for instance, this will result in products sticking together, which creates clusters in the fryer. However, by washing the cut potato slices in Rosenqvists Slice Washer System, it is possible to gently remove the free surface starch, that otherwise would affect the frying oil. Read more about washing cut potato slices in article The Guide to Wash Potato Slices.

Reducing Sugars

The available energy in the potato is the reducing sugars and this is also what gives the fried product its golden colour. If the content of reducing sugars is too high in the product, the colour will be brown instead of golden. It is therefore necessary to control the reducing sugars content, so that you may control the frying result over time when the product characteristics varies. This can be done by blanching the product, since it will open the cell membrane and will allow the reducing sugars to go from the concentrated area in the potato to the water. This diffusion cannot continue too long since it also affects the leakage of starch. If you lose too much starch, the final product will be soft, with a high fat content and you will also get a low yield. Rosenqvists recommendation of the sugar content per product type:

- Potato Chips are sensitive to a high reducing sugar content and should not exceed 0,2 – 0,3 % of the fresh weight.

- French Fries are not equally sensitive, but it is recommended to not have more than 0,5 % of the fresh weight.

Conclusion

To produce high quality potato products, the functions in the processing line must be flexible after possible quality variations in the raw material. It may be seasonal changes or the storing environment that affects the product characteristics, however, they need to be dealt with to have an even quality of your final product over time.

If the quality of your final product varies or if you simply want to upgrade your processing line, we offer the possibility to investigate your production and present alternative solutions of how to lift your product to the next level.