Fried nuts

Nuts

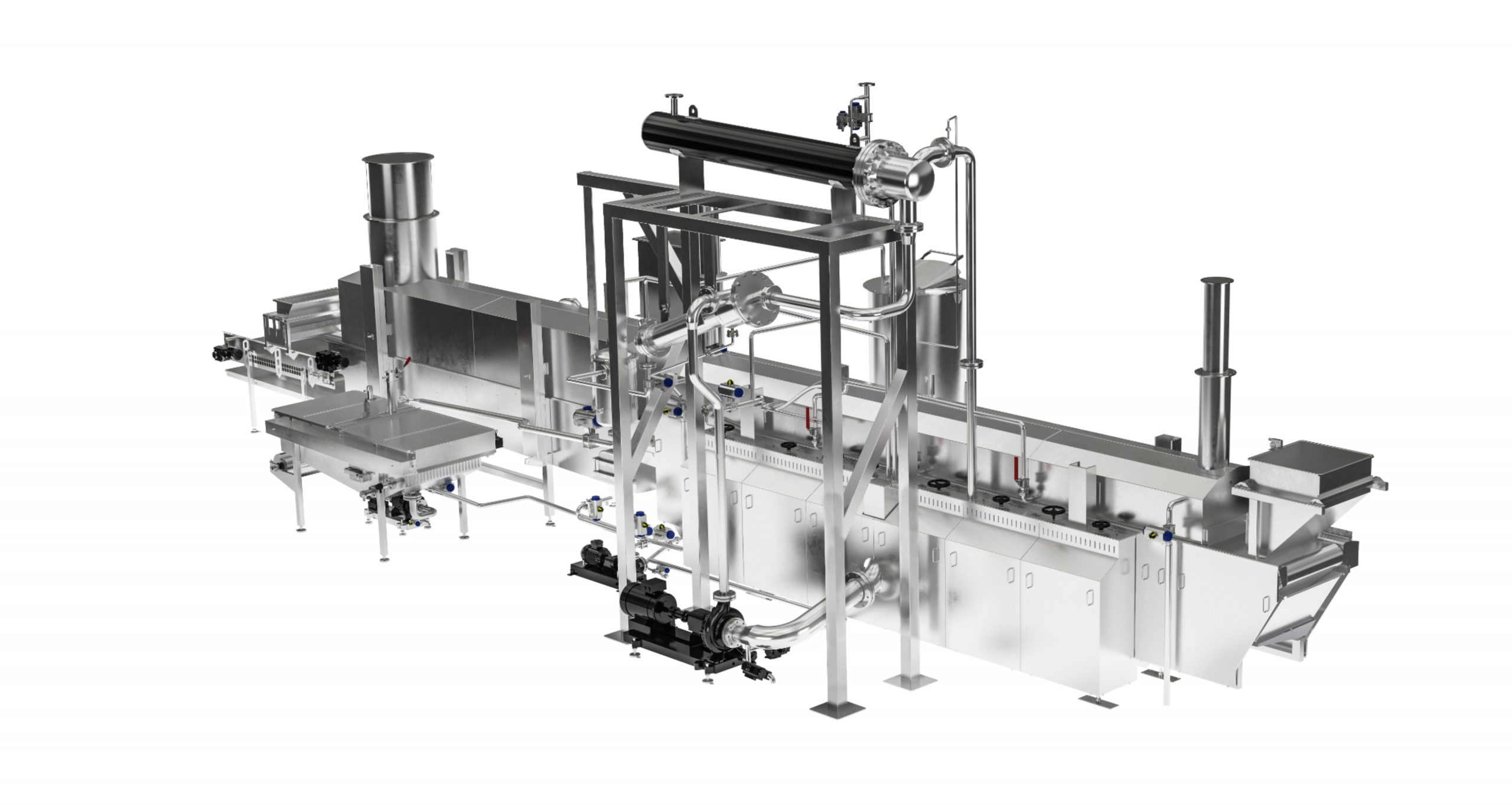

The processing steps

Infeed

In the first step of our nutfrying line we make sure to transport the right amount of nuts towards the frying. it is important to feed an even flow of product already from start. When we have ensured an even amount of nuts, we want to make sure that any broken pieces or embryos are removed before frying.

Frying

When the fines and broken pieces have been removed, the clean nuts are aligned over the complete width of the belt in the fryer, so that we can maximize the capacity of fried nuts and control the temperature profile accordingly.

Cooling

After the nuts have been fried, they are distributed to an air cooler to fasten the cooling process. the excess oil from that drips of the belt are collected and transported back to frying system.

Seasoning & glansing

The width of the belt in the fryer, cooler and seasoning belt are the same, so that we can maintain a consistent and even flow throughout the process. the salt or seasoning is applied over the complete width of the fryer and then glans-oil can be applied if desired. to even out any excess of salt, seasoning or glans oil, the nuts are sent to stirring, before being distributed to the packing.