9 November, 2020

The Ultimate Guide to Fry Potato Chips!

To fry perfect potato chips you need to control the raw material within the fryer, monitor the oil quality, filter and clean the oil, adjust frying temperatures, keep track of frying time, and a number of other factors. In this text, we will guide you through the key factors to successfully fry potato chips.

The Potato Slices

The aim with the frying process is to achieve a snack with great taste, with the appropriate amount of fat and the longest shelf life possible. This could be classic potato chips or thicker batch-fried snacks.

A fundamental condition for producing great potato chips is to use a potato variety suitable for snacks. You want to look for a variety with a high dry matter, >20 %, and the most stable storage characteristics. After cutting the potato in thin slices, approx. 1,4 mm for classic potato chips, you will need to wash and blanch the slices to remove free starch and reducing sugars. Just before the fryer, it is important to remove surface water from the slices and separate them. You want the potato slices to enter the fryer one-by-one.

Handling all slices identically is crucial during the frying process to achieve a consistent product quality. Therefore, you should look for a frying system were each potato slice is treated uniformly.

During the frying process, water is evaporated from each potato slice, ending up with a moisture level of <2 %. If you produce 1000 kg of potato chips per hour, a staggering amount of approx. 2700 kg of water is evaporated every hour! Consider and plan for the adequate amount of energy supply to your fryer and the possibility to take care of the steam.

Maintaining Oil Quality

Vegetable oil is a delicate ingredient that you need to monitor carefully. Choose a supplier of vegetable oil that can offer you a stable and consistent supply along basic advices. Four main “enemies” of the vegetable oil quality are:

- Oxygen

- Light

- Heat

- Catalysts (particles from the potato or metals for example)

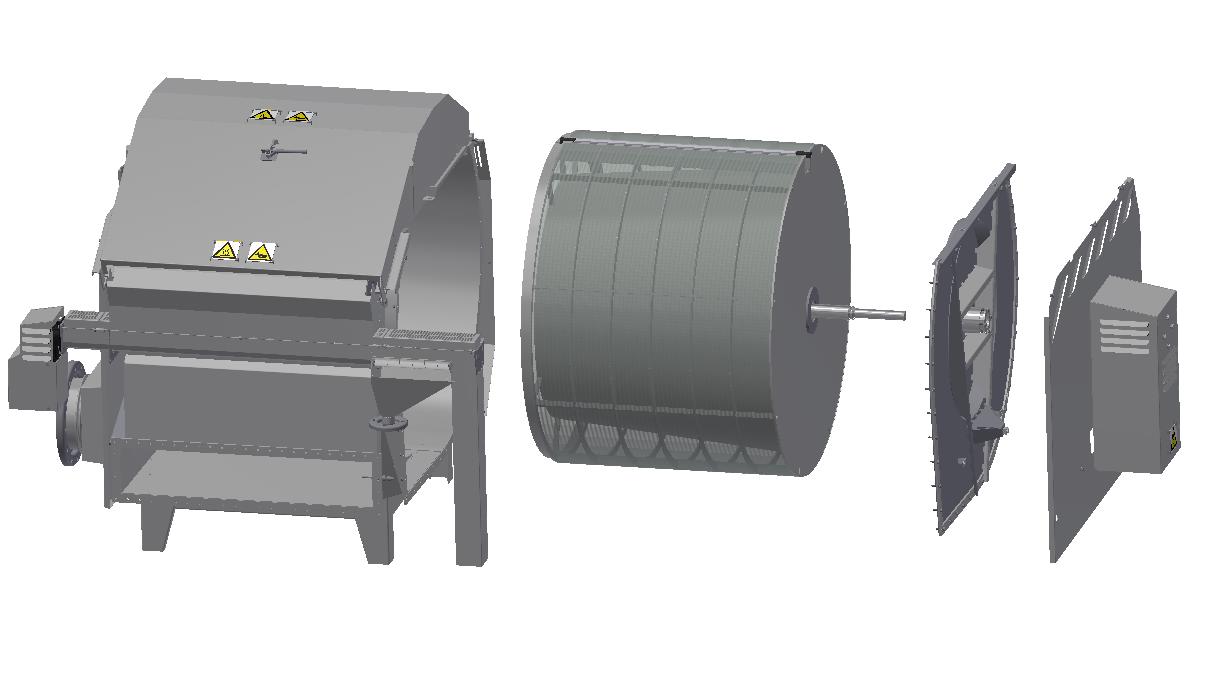

If you can protect your oil against the enemies mentioned above, you will become a master in frying. Look for a frying system that protects the oil from light and oxygen, where you can control the temperature along the fryer and that it is made of high-quality metals. It also must be easy to clean. At Rosenqvists Food Technologies we have invented a multi-zone fryer based on the highest demands to preserve and keep a high oil quality.

You can measure oil quality by analyzing levels of free fatty acids (FFA). Low levels of FFA will enable you to achieve the longest possible shelf life. A top-class filtering system and cleaning properties are also important to maintain oil quality. You should always strive to have the shortest possible turnover rate of the oil, so that you use as much fresh oil as possible.

Some key facts/estimations of the Rosenqvists process of producing 1000 kg of potato chips per hour:

- Oil uptake approx. 35 % or 350 kg/hour for classic chips.

- Volume of oil in the multi-zone fryer is 3 300 liters.

- The average turnover rate for the vegetable oil is 8 hours.

- Every drop of oil used is filtered every 40-50 seconds.

- You will need almost 4 kg of potato, 0,35 kg of oil and 0,06 kg of seasoning to produce 1 kg of finished potato chips.

Adjusting Frying Temperature and Time

During the initial phase of the frying process the starch granules will gelatinize evenly, creating a sticky surface on the potato slices. At 100°C the water inside the potato will boil and create an overpressure, initiating the evaporation of water. There is low fat absorption and almost no caramelization of the sugar. In this phase, you need a high frying oil temperature.

In the later stages of frying, the temperature of each slice is increased to 150-160°C while the water content evaporates. At this stage, the caramelization of sugars starts, and more oil is absorbed into the potato chips. The shape of the slices is finalized and the full taste and crispiness are captured. During this later stage, you wish to reduce the frying oil temperature.

For each step of the frying process, you want to be able to control the exact frying time and temperature. Classic potato chips are fried in approximately three minutes at temperatures ranging from 155°C to 175°C. If you produce batch-fried chips, the frying time is longer and temperatures lower.

Stay Below the Legislated Mitigation Level for Acrylamide

Acrylamide is a natural biproduct processing raw material. Securing low levels of acrylamide is required from all producers of potato chips. To minimize the risk of unhealthy levels of acrylamide, you need to make sure to have low levels of sugars in the raw material. The time for frying and the temperature of the frying oil, also needs to be kept low during the final frying stage to reduce this risk. Sugar levels can be controlled with a blanching process, where the sugars are leaked out in water.

In a multi-zone fryer, you can have the option to install a Cold Adjustable Temperature Zone (CATZ), where you fill the fryer in the end with relatively cold oil. By implementing this technology, you make sure the temperature is low towards the end of the frying process, which minimizes the risks of acrylamide build-up. Find out more about acrylamide and ways to avoid it by studying the toolbox from European Snacks Association, ESA.

At Rosenqvists Food Technologies, we have specialized our competence in frying for more than 45 years. Our designs are well tested and developed to offer the perfect control of frying. Do not hesitate to contact us if you have any questions about frying. We are happy to assist you to produce the perfect potato chips.