17 May, 2021

3 Upgrades for Potato Sticks Production

Rediscovering a classic snack product is made easy with Rosenqvists Food Technologies

Potato Sticks is a classic snack product. It is loved and consumed as a stand-alone snack or as a condiment to your grilled barbecue dinner. Why not rediscover this product, a perfect complement to your range of potato chips. Patrik Kjell from the service team at Rosenqvists Food Technologies summarizes what upgrades you need to make in your processing line to produce potato sticks.

1. New cutting head

A typical cut size for potato sticks is 3.6 mm X 4.8 mm. You need to upgrade with a new Head Assembly for strip cut and an impeller if you are working with Urschel cutting systems. If you work with FAM cutting machines, it is enough to replace the cutting head by the julienne cutting head.

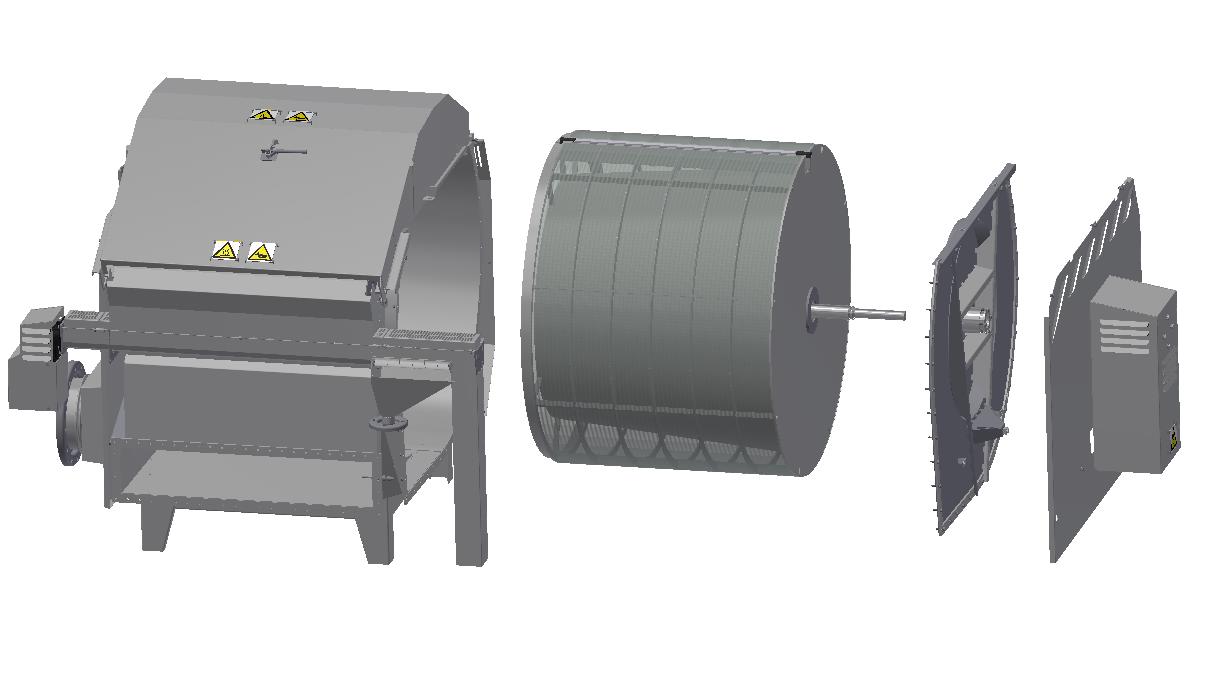

2. Adjust nets and belts for potato sticks

After cutting, you need to make sure nets, sieves and belts used in vibratory conveyors and other processing equipment is of right dimension. In the Rosenqvists processing line, it is enough by just exchange sieves and an extra net outside the washing drum in our 3-step slice washer. A simple operation requiring a few minutes for mounting.

3. Adjust frying settings

A suitable target for moisture of the end product is 1.6-1.7%. A process engineer from Rosenqvists Food Technologies can support you in setting up a new recipe for the frying process with the appropriate setting for temperature and frying times in each frying zone. It takes a few hours to train your operators to achieve the right bite of the potato sticks.

Check out this short film showing you how potato sticks are produced.

Contact us at Rosenqvists Food Technologies if you want to upgrade your chips line for potato sticks production.