26 April, 2020

Fantastic Frying of French Fries – 4 key Factors to Succeed!

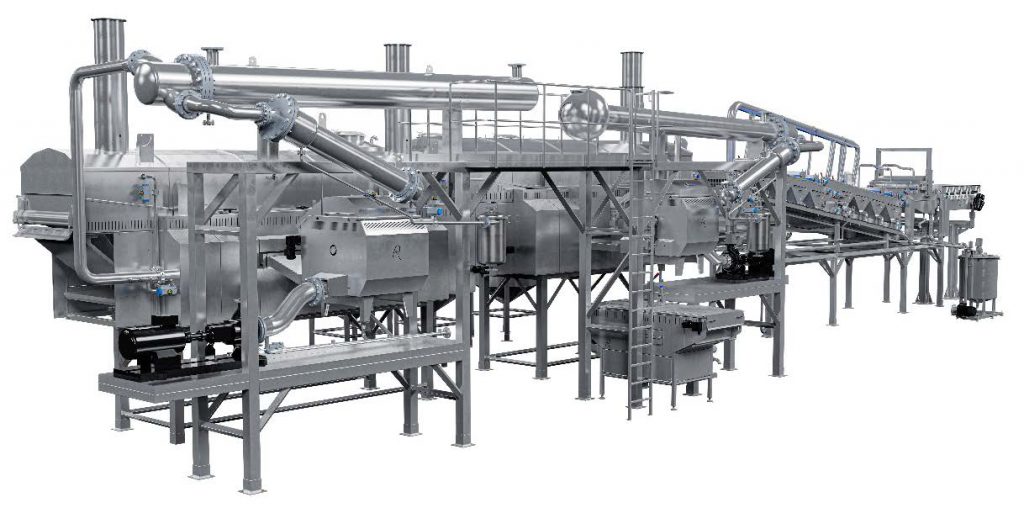

The processing of French Fries has been optimized over several years by companies like Rosenqvists Food Technologies. The market for frozen French Fries is global and represents interesting growth opportunities for producers all around the world. At Rosenqvists, we take great pride in our frying solutions and in this text, we summarize our key learnings for successful frying of classic and coated French Fries.

Different Types of Cut Potato Products

Classic French Fries is a typical cut potato product with several different variations of it. Thickness and shape may differ, you may even want a specific length or pattern in the cut, or perhaps cover it with coating.

What is Coating?

You have most likely come across a cut potato with coating. Coating is a fluid mix (batter) that is applied on the product before it is fried. You can say that it is a thin layer on the surface enhancing characteristics such as crispiness, fat uptake, color or for an extra touch of flavor. Read more about coating and this equipment in our article How to Coat French Fries and Other Cut Potato Products.

1. Design the best frying system

– Single or Double-Frying System

When producing classic French Fries, you need a single frying system, in which the Fries are fried from start to finish. However, if you are interested to produce a coated potato product, you will amongst other equipment in Rosenqvists concept use two fryers instead of one.

Upgrade to a Coating Line

If you already have a current processing line for French Fries or other cut potato products, with a single fryer, it is possible to upgrade it to a coating line with an additional fryer.

Before entering the double-frying system the French Fries need to be singulated in the aligning feeding shaker to ensure that products are fed evenly and separated into the 1st stage fryer.

1st stage fryer

A first stage fryer can be installed before your already existing fryer. The purpose of this first stage fryer is to adhere coating to product surface so the fries do not stick to each other. This is made during a relatively short frying time, approx. 15-20 seconds. The Fries are transported in a controlled way one by one making sure the coating is set and stable.

2nd stage fryer

The second stage fryer is used for finalizing the frying of the product, usually 45-60 seconds. Due to longer frying time and the set surface coating, the product bed can be loaded higher in this second stage fryer.

2. Controlled Product Flow

Every single strip of French Fries should ultimately get the same frying treatment regardless of where its location is in the fryer. A single-layer product flow in the 1st stage fryer and a higher product bed in the 2nd stage fryer of 80-100 mm.

In both fryers it is crucial to have a laminar oil flow throughout the width of the fryer ensuring smooth equal transport and processing of each French Fry. The laminar oil flow is of extra importance in the 1st stage for keeping the individual strips separated and to control oil velocity ensuring that the coating is set onto the product and not washed away.

3. Best-in-Class Oil Management

Oxygen, light, high temperature and water from the product will cause deterioration of the frying oil. The focus of the Rosenqvists design is to achieve the best oil quality over the longest possible time. We supply frying systems for French Fries with the lowest total oil volume on the market and our secrets are high quality oil-flow and circulation system.

An outside belt return minimizes the oil level in the frying pan and enables continuous cleaning of the belt. Our multi-flow oil system, with several temperature zones, creates an optimal control of the frying and therefore also an increased control of the oil flow within the fryer. Thanks to this frying technology, we can offer a cost-efficient solution since you do not waste any heat or oil. By doing this, we also minimize the risk of over-frying products, which in return also maintains a high quality of the frying oil over time. With the Rosenqvists fryer, the oil quality is maintained so only fresh oil is added and no oil will be wasted.

Complete Filtration System

Keeping the oil clean will result in high quality products, with great taste and texture. Our complete filtration system when producing French Fries, includes a Continuous Drum Filter, a Centrifugal Filter and a Fine Filter.

The Continuous Drum Filter cleans the complete oil volume of the fryer every 45 seconds and catches all large debris from the fryer. In the next filter step, to get rid of the finest waste particles, the oil enters the

Centrifugal Filter that separates waste by gravity. Heavy waste particles are then forced towards the fine filter that finalize filtering of the oil to required level. Another great feature of our frying system for French Fries and cut potato products, are Teflon scrapers integrated in the fryer belt facing the pan bottom, collecting debris towards a waste collection system, for easy handling of the waste.

Our filtration system allows the producer to run continuous production of French Fries up to 21 days without cleaning.

4. A Long-Term Partner

We have developed frying systems for French Fries for more than forty years. Providing stable and long-lasting frying systems for our customers.

The Rosenqvists frying system allows for a minimum of oil circulated in the system, quickest oil turnover rate maintaining the best oil quality for the longest time. Outside belt return is a unique design from Rosenqvists. The heat transfer is more effective due to very low and even turbulence created by the Rosenqvists in- and outlets design.

Conclusion

Whether you are planning to produce classic French Fries, Wedges, Crinkle Cuts, or another cut potato product, we can build a frying system that fulfills your need. We have wide experience in building frying solutions for different cut potato products and we know that our frying system for French Fries can be used to produce them all.