5 May, 2022

The efficient 3-step slice washing system

The 3-step slice washing system is used in potato-chip production industry to wash away surface starch from potato slices after cutting. With the latest development by Rosenqvists Food Technologies, the system is further developed, offering some unique features. In this article, Magnus Kalling, the R&D Manager at Rosenqvists Food Technologies, summarizes the reasons for washing potato slices and explain why the 3-step slice washing system is such an efficient system.

Basic factors for washing potato slices

The potatoes are sliced to a thickness of between 1.1 and 2 mm, depending on the required product. When cutting, the cell membranes as well as cells is opened/damaged. The cell fluid containing free amylose and other substances as well as the inner starch granules, leaks out as ”free starch”. This causes a considerable tendency towards stickiness during frying and the slices are thus washed prior to this operation to eliminate this problem.

Several differently designed slice washers have been developed in the past thirty years, after potato chips started to be manufactured in industrial scale. Line capacities have risen to an hourly production capacity of over 3,000 kg of finished potato chips, with an approximate hourly input of around 11,000 kg of potato slices.

At this capacity and with a slice thickness of 1.1 mm of the sliced potatoes, it is possible to calculate that a surface area of over fifty square metres (>50m²) must be washed every second. Water consumption usually exceeds one cubic metre per tonne of potatoes (>1 m³/ton) and is therefore considerable.

As the lines operate on three-shift production schedule, with minimal downtime for cleaning, there is a gradual starch build-up on all surfaces of the fryer that in time increases to such an extent that production is disturbed, and cleaning becomes necessary.

The cause of this build-up in the fryer, is the residual starch granules that float around in the surface water around the chip slice. These are not bound to the potato slice and float with the frying oil; after a few seconds the starch is rendered adhesive, and the water begins to evaporate. The starch granule now undergoes a phase in which it is very sticky and adheres easily to metal surfaces as well as other surfaces.

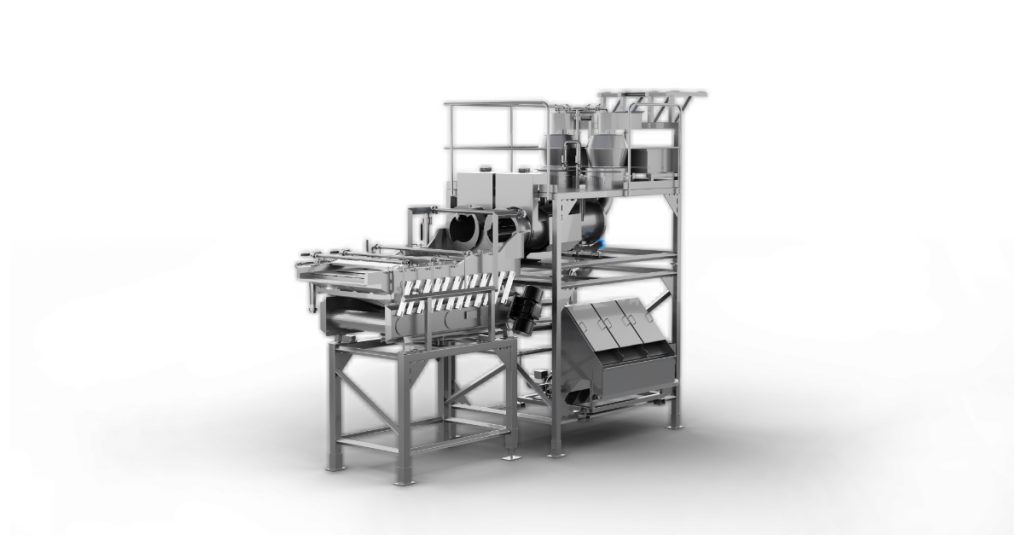

The slice washing system that Rosenqvists Food Technologies has designed, implies in principle that washing is performed in several steps, where the water is separated and cleaned of particles, to be subsequently pumped back to a preceding stage. In this manner, the slices encounter the cleanest water upon exit and this water is then use in preceding wash stages.

This concept is logical, but the challenge lies in producing a design that at one and the same time is hygienic, minimizes foaming effects, efficiently utilizes floor space and can be practicably adaptable to the layout of different plants. The 3-step slice washer from Rosenqvists Food Technologies solves all challenges above.

The principle of the 3-step slice washing system

Wash step 1

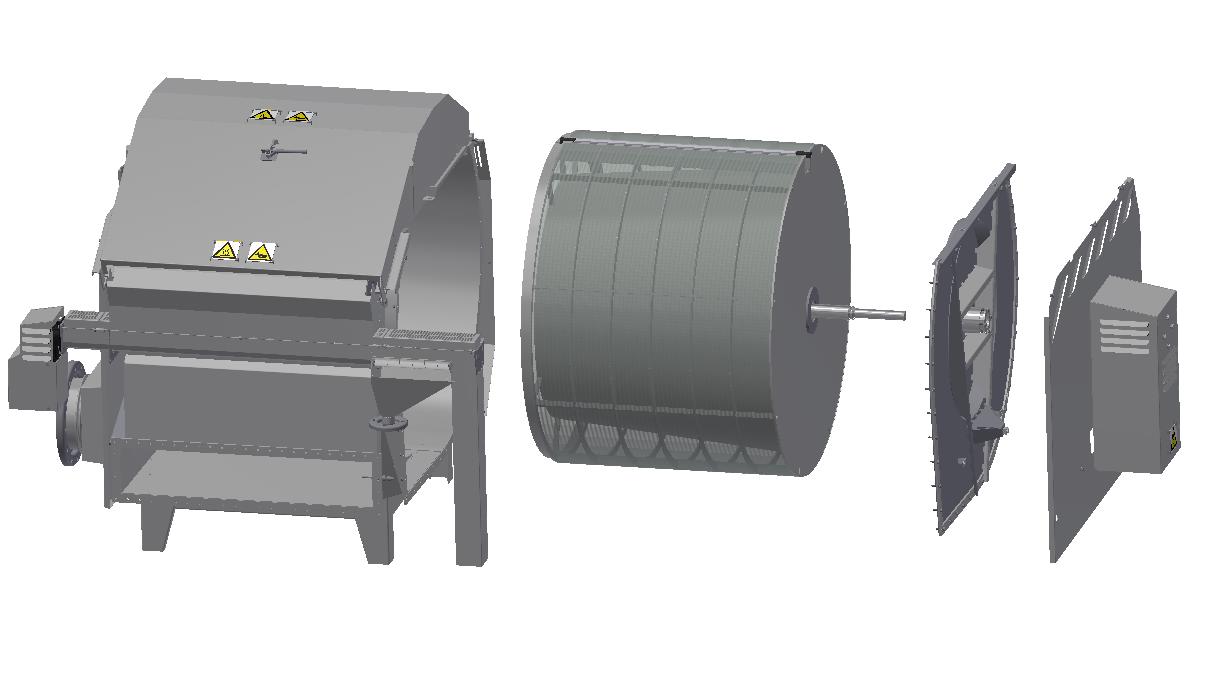

Washing already starts with the slicing operation. This stage is important because the slices are separated from each other together with a liberal amount of circulated water. Slices and water flow over into a rotating tube (one for each slicer). The first section of the tube tapers conically outwards to a larger diameter and then inwards to a smaller one.

The unit tumble the slices and water. In this first wash step, the starch concentration in the surface water is reduced to 1:10 and the surface water layer around the slice is now 0.13 mm.

The next section of the tube is a perforated sector where the bulk of the starch-enriched washing water is separated. The free starch content in the surface water is 20-50 ml/kg of slices.

Wash step 2

The tube now tapers conically outwards again to a larger diameter and the slices now encounter fresh, cleaner water, while two drivers ensure that the slices and water are tumbled. The tube ends with a cone shape that ensures water level in the tube.

Slices and water flood over the edge into a de-watering shaker. The washing water is separated (free starch content 6-20 ml/kg of slices). After a first de-watering section, a further flushing is undertaken with water from step 1.

Wash step 3

Undertaken after de-watering via spray nozzles above and from below the shaker table. Free starch content in the surface water is now down to a magnitude of 1-3 ml/kg of slices, optimal for smooth frying.

Water flow

Water handling is done via a pump tank with three sections. The water from step 3 is strained and collected in section 3 of the pump tank and pumped to wash step 2. The washing water from step 2 is strained and collected in section 2 of the pump tank and pumped to wash step 1. The washing water from step 1 is strained and evacuated via an overflow. The pump tank is so designed that irrespective of a supply of fresh water, there is always water for the pump circulation in that water can flow backwards through an aperture between the sections. Pump tank stage 1 is provided with an extra pump and two hydro-cyclones to raise the starch concentration in the wastewater and lower that in the circulating water.

Features and benefits with the 3-step slice washing system

- Gentle handling, no breakage of product.

- Controlled product flow. Same washing effect of all slices.

- Removal of small potato particles over three sieves.

- Defoaming agent not in contact with washing water.

- Easy to clean.

- Open and proven design. Easy to maintain.

- Exchangeable screening net for optimal final product quality.

- Low water consumption (1 lb of water/1 lb slices)

- Only 1 ml of free starch in surface water per 1000 gram of slices entering frying system.

At Rosenqvists Food Technologies, we have more than 45 years of experience in designing processing lines for potato chips. Contact us if you wish to find out if the 3-step slice washing system can be an improvement for your processing line.