Fried pellets

Fried pellets

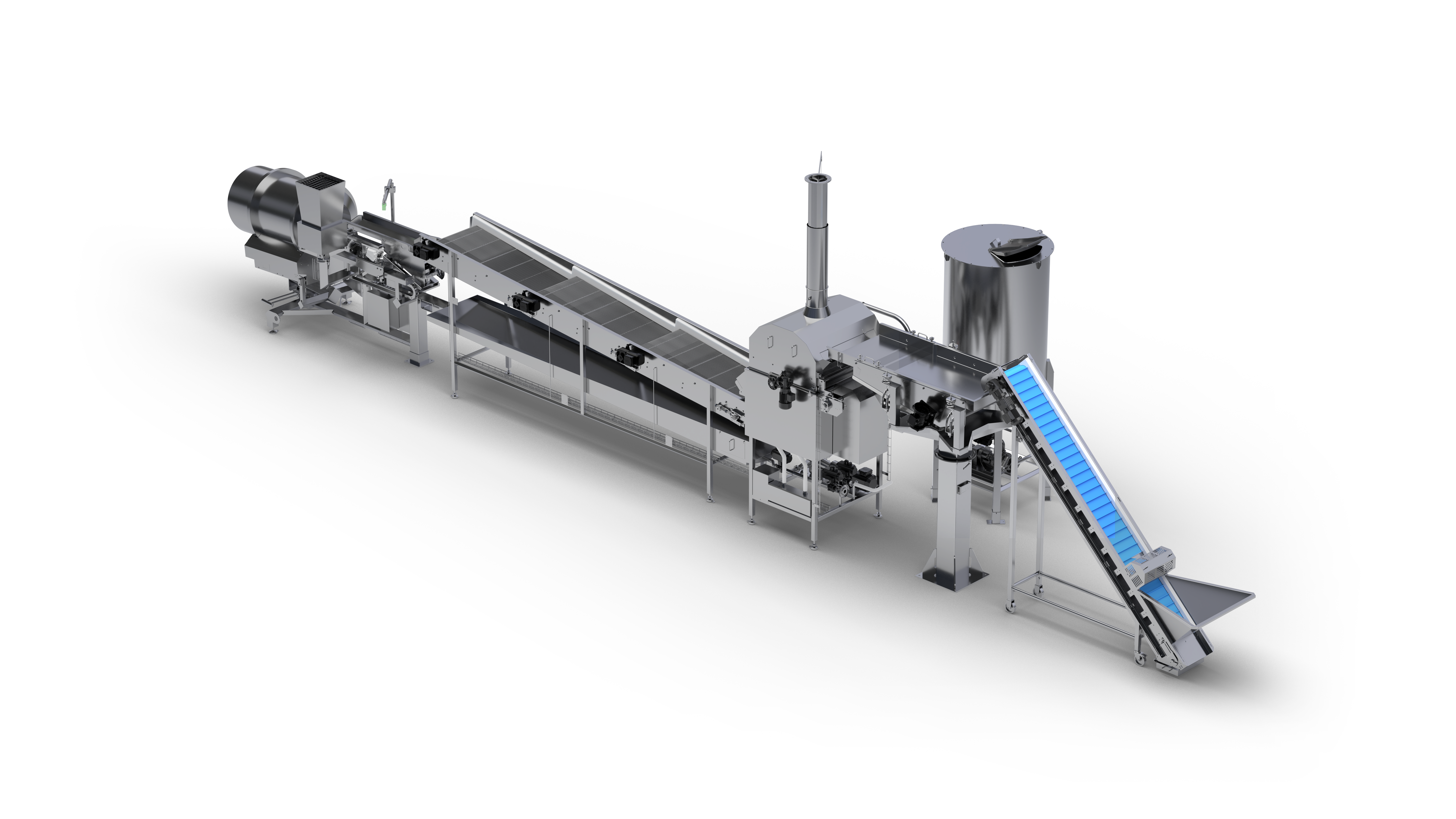

The processing steps

Infeed

In the first step of our pellet frying line we make sure to transport the right amount of pellets towards the frying. This is made with our Infeed Elevator that ensures an even flow of product already from start. When we have ensured an even amount of pellets, we want to separate them before the fryer, so that each pellet can get the necessary energy and room to expand. For this task we use VibRD, that is a vibratory conveyor.

Frying

Our patented Star Wheel Fryer can ensure an exact frying time since each pellet falls to a separated space in the rotary fryer. This portioned space allows the pellet to expand properly and have an exact in- and outfeed time. The frying time can be adjusted to the requirements of the snack pellet you want to fry. When the pellets have been fried, they fall to next step in the process.

Star Wheel Fryer

Cooling

The pellets are now fully expanded and needs to be cooled off before the seasoning can be applied. To take advantage of the excess oil, the products are turned one or two times on our Drip-Off Belt before entering the seasoning. The oil below the belt is collected and pumped back to the frying system.

Drip-Off Belt

Seasoning

The final step is to apply seasoning to the product. To make this process as accurate as possible, the flow of product must be even and consistent so that no seasoning goes to waste. To make sure the whole surface area of each pellets gets covered in seasoning, we have designed the SEABASE system that measures both product and seasoning. Also, our seasoning drum allows the pellet to turn multiple times whilst being seasoned and at the same time it is transported forward towards the packing area.