19 February, 2019

3 Success Factors for Perfect Seasoning of Snacks

Seasoning of potato chips and other snacks is the delicate process where you give your product the taste and look you desire. During this step in the process, you would like to achieve an even coverage of the product with the exact amount of seasoning. So, what are the key success factors for the perfect seasoning of snacks? We will guide you through the fundamentals of seasoning. An accurate seasoning system is the guarantee for a great snack product, but also an insurance to control your production economy. Great savings can often be made with a professional seasoning system.

1. Even Flow of Snack Product

In a good seasoning solution, you will need consistency and limit the number of unwanted stops in the production. Every stop will unfortunately mean some variation in the application of seasoning. An even flow of snack product entering the seasoning drum, enables you to always apply seasoning according to your recipe. If you want to apply 6 % of seasoning, an even flow is a pre-condition to make this happen. To achieve the even flow, you will need a buffer where you accumulate product. The product is then transported on vibratory conveyors to even out the product.

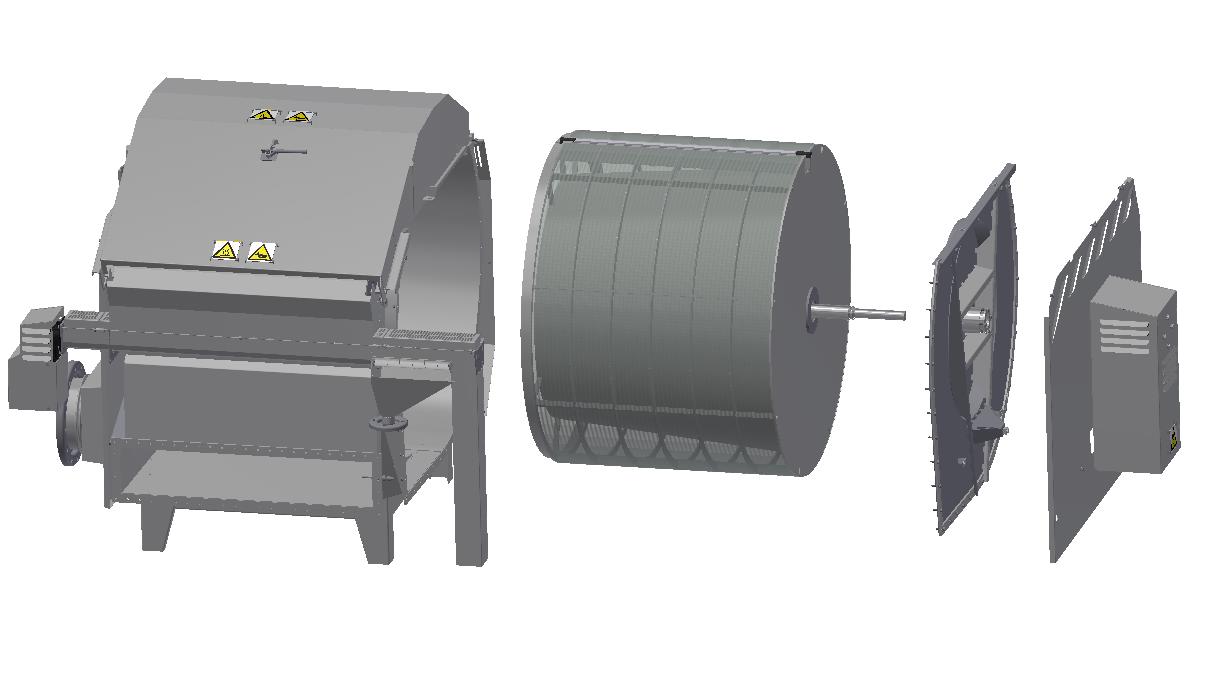

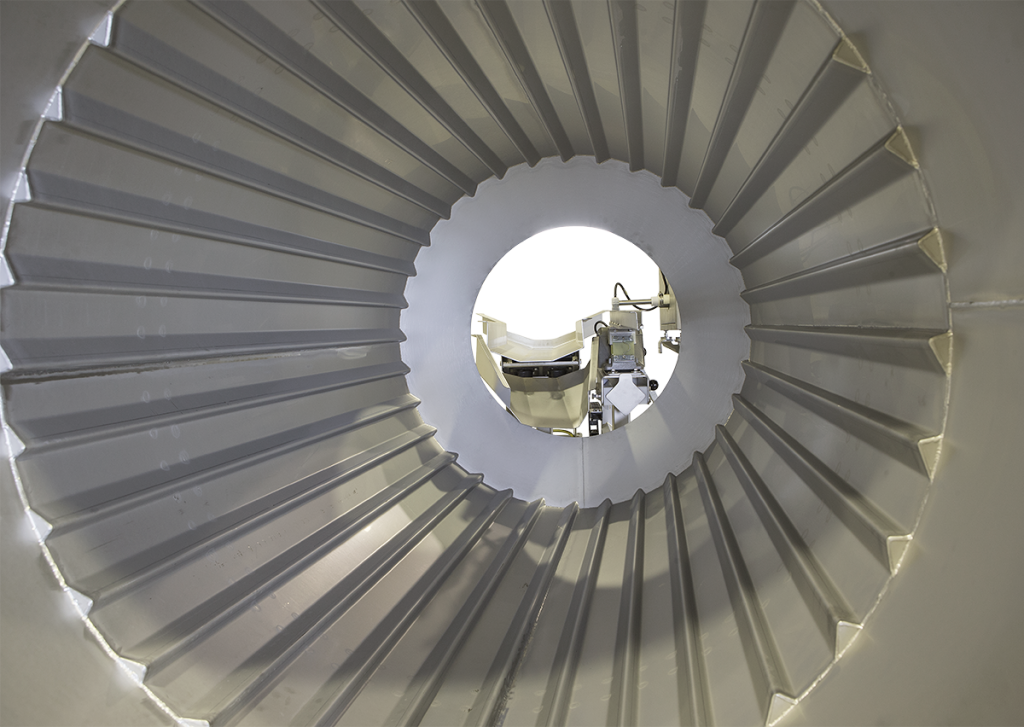

2. Seasoning Drum Performance

The seasoning is usually applied in a rotating drum where the potato chips is kept in motion and slowly moved forward. It is of utmost importance to create the perfect “surf wave” of product inside the drum, not too high. If you do this right, you can get the best possible

coverage of seasoning. A gentle handling of the product, the perfect “surf wave” and an exit where the snack lands smoothly, are factors influencing the drum’s seasoning performance.

3. Accurate Feed of Seasoning

Seasoning is fed onto a scarf feeder with a bias-cut exit. Here, seasoning is slowly shaken forward into the seasoning drum. The challenges are to achieve a good spread of the seasoning and an even speed forward. If you can manage this, you have all tools necessary to control the application rate of your seasoning.

Conclusion

In addition to the three success factors listed in this text, there are other aspects of importance influencing perfect seasoning of snacks. The temperature of the product and the amount of oil affects the ability to glue the seasoning to the snack. Different seasoning blends have also different properties for sticking to the product. Talk to your supplier of seasoning to get the right particle sizes and ingredients in order not to waste seasoning.

If you want support to build an even flow of product in your seasoning system or increase your drum performance, Rosenqvists Food Technologies can give you the help you need. We can assist you with running Catch tests, installing weight sensors for increased accuracy of applied seasoning and programming logic to reach your desired level of performance.