30 January, 2023

5 tips to save energy when producing potato chips

Producing potato chips requires a lot of energy. Long-term, there are many plans for possibilities of running this process with the help of recovered energy. But what can be done today – short-term, without commercial break-through for heat pumps and other ideas on pilot scale? At Rosenqvists Food Technologies, we asked our R&D Manager Magnus Kalling to investigate what is possible to implement short-term. Niklas Möllerstedt has summarized the five best ideas in this article.

Energy supply and price of energy represents significant challenges for all producers of potato chips today. Luckily, there are some great opportunities out there to help you save energy. The first and most important criteria for using the minimum amount of energy is to establish an efficient production in general. Improve your process to have small waste streams, utilize the potato as efficient as possible and invest in long-lasting processing equipment with a minimum of heat and raw material losses. We assume you have done all this already so we then asked ourselves, what can you do on top of your already efficient production?

1. Product temperature of chips slices

When frying potato chips, you need to heat up the chips slices to the desired temperature in the vegetable oil. Naturally, the temperature of the chips slices going into the fryer has a major impact on the energy used to reach the right temperature. If the chips slice is 20 degrees Celsius at the infeed of the fryer, you need more energy to heat it up to 140 degrees at the fryer outfeed comparing to a situation where the chips slice goes into the fryer at 60 degrees Celsius.

There are some obvious ways to increase temperature of the chips slice before frying. One is to blanch the slice in hot water. If you are not using a blancher in your process, you can still heat up the product temperature. By installing a stack condenser to your fryer chimney, hot water can be generated with the help of the fryer vapors. This water can be used on a dipping belt or in your slice washer system to increase the product temperature. Using “free energy” from your frying system can be a smart investment.

In the below example of possible energy savings from increasing temperature of the chips slice before the fryer our calculations are based on a production of 2500 kg/hour.

Estimated energy use at 20°C chips slice: 1165 kWh

Estimated energy use at 60°C chips slice: 818 kWh

Possible savings of energy is 350 kWh

Considering an energy price at 0.30 Euro/kWh, you can save 12 600 Euro/week or 605 000 Euro/year!

2. Surface water on chips slices

The chips slices going into the fryer are wet after being washed, dipped or blanched in water. This surface water needs to be evaporated inside the fryer along with the water inside the slice itself. Energy is being used to evaporate all water, both the surface water as well as the natural moisture inside the chips slice. Following this analogy, the less surface water on the chips slice, the fewer kWh used in the frying process. It would be logical to dry away as much surface water as possible before the fryer following this logic but be careful. You will need some surface water to make the slices slide off each other avoiding lumps of potato chips in your product bag.

You can reduce the surface water by using vibratory dewatering conveyors, high-speed belt with air blowers or other technology. Feel free to get advice from our sales managers what could be the best option for you in your processing line. You can also get advice on how to measure amount of surface using a simple method with a centrifugal sieve.

In the below example of possible energy saving by reducing the surface water on chips slice we base our calculations on a 2500 kg/hour production of potato chips.

If we assume you can reduce surface water from 12% to 8%, estimated savings are 320 kWh.

Considering an energy price at 0.30 Euro/kWh, you can save 11 500 Euro/week or 553 000 Euro/year!

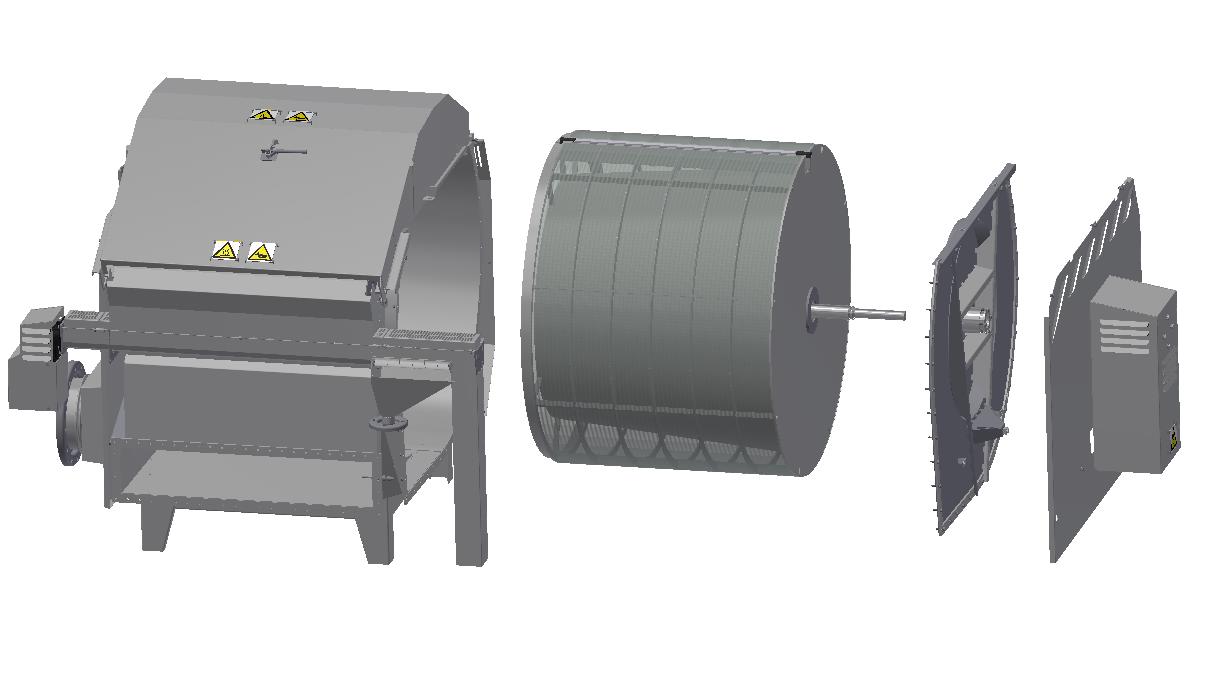

3. Insulation of the fryer hood

Most of the chips fryers used in the snacks industry today are not insulated. This means also that you risk facing significant heat losses through the uninsulated surfaces surrounding the fryer. Consider your next chips fryer with an insulated hood or check if you can re-build your existing fryer. In many cases, a re-build is possible and can be implemented during one week of production stop. The customer service team from Rosenqvists Food Technologies can support you with an offer for your fryer.

How much energy can be saved by insulating the chips fryer? Based on our technical estimations, you can reduce heat losses to 1/6 of the heat loss you currently experience by insulating the whole system. The is equivalent to a saving of approximately 500 W/m2.

In the below example of possible energy saving by insulating the chips fryer we base our calculations on a 2500 kg/hour production of potato chips. If we assume a reduction of heat loss in the fryer of 500 W/m2, estimated savings is 12.5 kWh.

Considering an energy price at 0.30 Euro/kWh, you can save 450 Euro/week or 22 000 Euro/year!

4. Optimize the production schedule

Every time you need to stop your production whether it is for cleaning or for a break before the next shift, you will spend additional energy without producing valuable potato chips. This is something you want to avoid at all costs. Can you move the current 2-shift operation over five days into a 3-shift operation of four consecutive days instead? Can you increase production on one processing line to a 3-shift operation over the full week? Establishing a long-term consistent production will guarantee an efficient use of energy. The same thinking applies to handling production variations in terms of capacity, moisture level and uneven final product quality. By training your operators to master these variations to perfection, you will maximize production yields and use energy efficient. With some improvements you might be able to produce potato chips an additional 24 hours before you need to stop for cleaning. You can book a process optimization training course together with our specialists in case you need a speaking partner.

5. Source potato with appropriate dry matter content

A final and obvious recommendation is to source potato with the right quality. Processing a potato with a dry matter content of 22% is very different from processing a potato at 20% dry matter. If you can secure supply of potato at high dry matter, you will save a lot of energy.

In the below example of possible energy savings by purchasing potato with desired dry matter we base our calculations on a 2500 kg/hour production of potato chips. If we compare energy requirements for a 22% dry matter versus 20% dry matter, estimated savings is 658 kWh.

Considering an energy price at 0.30 Euro/kWh, you can save 23 700 Euro/week or 1 137 000 Euro/year.

Bonus tips: Did you know you can convert the heat from the fryer chimney into hot water?

Yes, this is possible with a stack condensing system from Rosenqvists Food Technologies or other supplier. A practical way to turn energy from the energy intensive frying process into hot water that you can use for the blanching process, for cleaning purposes, for heating or for other energy saving actions.

Further reading:

Apart from the energy tips above, check out also our recommendations on how to save water in the article by Richard Rosenquist, “Processing of potato chips – Six tips to optimize water usage”.