30 March, 2022

Processing of potato chips – Six tips to optimize water usage

Water is used to produce high-quality potato chips for many good reasons. But water is a scarce resource and producers of chips are working hard to minimize the usage of water. What can you do to optimize the usage of water? In this article, our project manager, Richard Rosenquist, explain why water is needed in your production and the six best tips for optimal water usage.

Water is an investment for a long production cycle

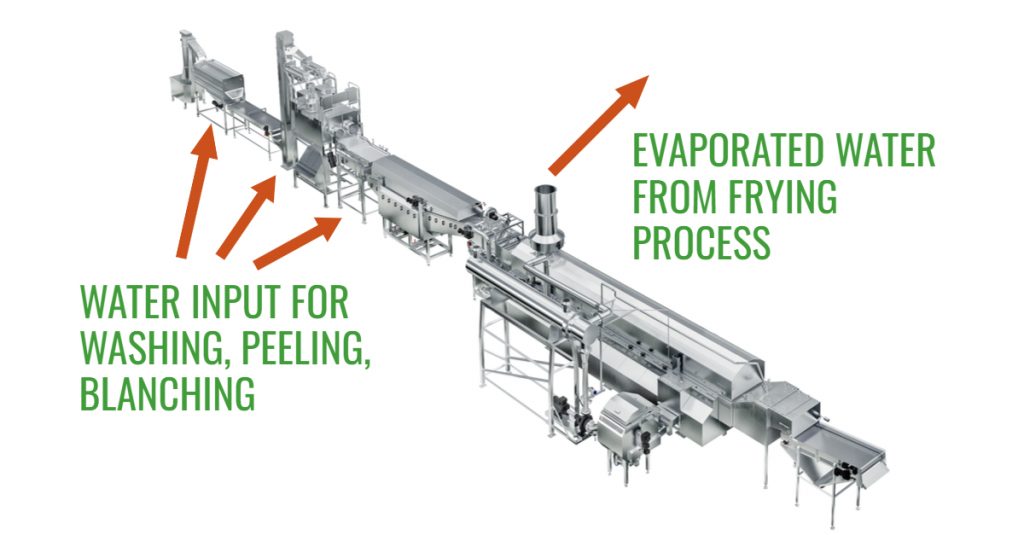

Potato consists mostly of water which is removed during the frying process of potato chips. Water is also essential for a good preparation and process of the chip’s slices before the fryer. The water is used for cleaning purposes of whole potato, washing of chips slices, blanching of slices and of course for cleaning the processing line during planned production stops. Using water in your pre-line is a condition for long production hours. If you use the water well, the less sugar, starch and debris ends up in your frying system which means you can run your production many days without the need for production stop. Therefore, water is a necessary investment for the longest possible production cycle.

The process steps where water is used

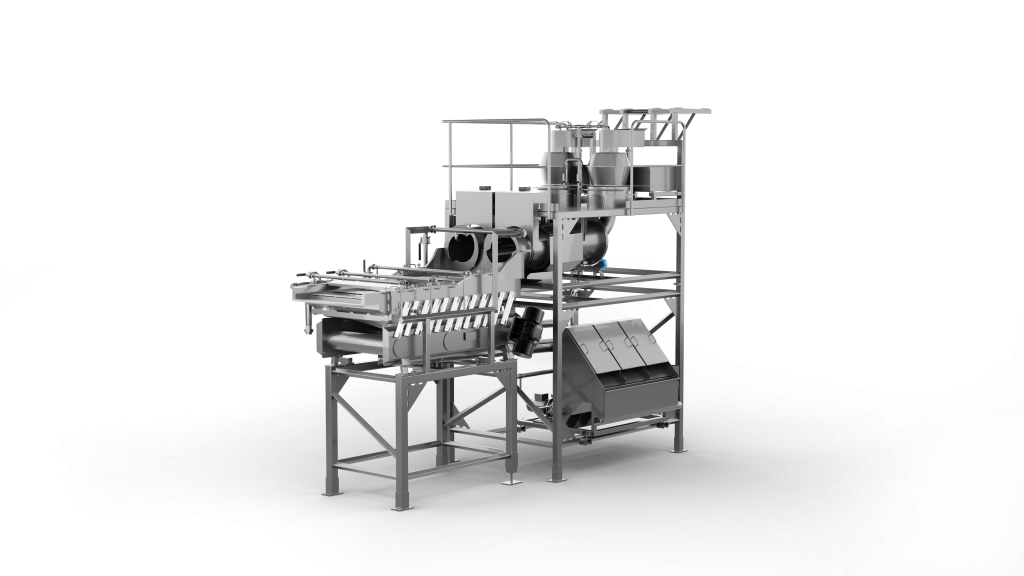

If necessary, remove stones and soil with water in the cleaning stage. Here, you can use recycled water from slice washing or peeling. It is recommended to use only for a limited time, and at low temperatures to minimize any risk of bacteria growth. The residual dirt that is generated in this step can be taken back to the growing fields if possible. Next step in the process is peeling. Water is not necessarily needed to peel the potato, but it is used to transport the peel waste out from the machine. You also need some water to clean the surface of the potato before inspection and cutting. The waste with potato skin contains energy and can be dried and used for animal feed or biogas. After the cutter, starch is released on the chip’s slices. A good slice washing system is used to remove all free starch from the slices. At Rosenqvists Food Technologies, we have conducted a lot of trial to achieve the perfect rinsing process. Our 3-step slice washer is designed to rinse each slice three times re-using the water after each rinsing step. By doing this, we can guarantee to remove as much free starch as possible and to minimize the volume of water used. Thanks to the patented design, the 3-step slice washer is using 1/3 of the water needed for washing compared with a standard washer. There is only 1-3 ml of free starch remaining on every kg of slices after the three rinsing steps. The starch removed with the slice washer can be recovered turning it into a valuable resource with the help of a starch recovery system.

Blanching is then used to leak out sugar from the chip’s slices. At low sugar levels, the blanching step can be bypassed. Still, when blanching is applied, hot water is used, and the volume needed is in direct relation with the content of sugar. The water stream coming out from the blancher contains gelatinized starch and is not suitable to re-use in other parts of the process. You need to clean this fraction biologically or chemically. Pulse Electric Field-technology (PEF) is a technology sometimes used before cutting potato in chips slices. This technology perforates the potato cell walls and minimizes the cutting losses. Even when applying PEF-technology there is still a need to wash away free starch and leak out sugar, so water consumption is still needed.

Finally, water is used during the cleaning cycle when production is standing still.

Six tips for water management

After all these steps, the slices for potato chips are ready to be fried. No need to add more water in the process, quite the contrary, now is the moment where you remove the water from the potato. Let’s find out what you can do to optimize the usage of water in your plant. Here are our six best tips.

1. Clean the potato at intake

Potato is harvested in different ways and the soil condition varies a lot. At the potato intake, you can use a mechanical soil extractor removing most of the clay, sand or dirt that comes in with the potato. Cleaning the potato in a good way at intake gives you the best condition for using minimal water later on in your processing line.

2. Re-use the water from slice washing and peeling

The water from the slice washing step as well as the peeling system can be re-used several times. By setting up a water circulation system, you can maximize the usage of this water. As mentioned earlier, avoid the risk for bacteria growth by securing low water temperature and limiting the time the water is used.

3. Utilize the waste stream from peeling and slice washing

Peel waste contains energy and can be used as a resource for animal feed or as fertilizer. It can also be converted into energy by installing a biogas system. The waste stream from the slice washer contains starch. Here, it is possible to convert the starch into a valuable product by installing a starch recovery system.

4. Monitor water usage for blanching

By measuring the sugar level in the blanching water, you can optimize the amount of water used in the multi-turbulent blancher. Low levels of leaked out sugar means you can lower the volume of water added in this process step.

5. Stop and clean as few times as possible

When cleaning out the frying system and all other machines, you will need to use a lot of water. Some of this water is not suitable to re-use because of use of detergents. By designing the processing line and by keeping the frying system as clean as possible, you only need to stop and clean perhaps once per week. This will save you significant amount of water and it will maximize your production capacity. The design from Rosenqvists Food Technologies always focuses on cleanability and your ability to run production over several days without unnecessary production stops.

6. Re-use energy from the frying system to heat up water

The hot vapor collected in the chimney of the fryer can be converted into hot water. This can be achieved with the help of a stack condensing system or other equivalent options. This smart investment creates a good source of hot water that you can use for blanching, cleaning or other purposes in your production plant. Make sure you re-use as much as possible of the energy utilized in your frying system.

At Rosenqvists Food Technologies, we have more than 45 years of experience in designing processing lines for potato chips. We know that all sites are different with different conditions for raw material, access to water, different cost for water and different cost for energy. Contact us if you wish to discuss the best options for you and your factory.

Good luck in utilizing water in the best possible way!