7 April, 2021

How to Reduce Acrylamide in Your Process

It is commonly known that acrylamide is bad for you and that it is a natural biproduct when cooking raw materials, but is it possible to reduce or even eliminate this contaminant in the process?

Background

All raw materials have a certain amount of amino acids and sugars, since it is a part of the photosynthesis. You can say that the raw material is naturally programmed to store energy to survive and procreate over time. When amino acids and sugars are heated, when frying, baking, or roasting for example, it is a chemical reaction that the acrylamide appears as a biproduct. Therefore, the amount of acrylamide can never be eliminated in the process. However, the amount of acrylamide in the processed product can be significantly reduced by combining knowledge about the raw material with the right technology.

Legislation

The 20th of November in 2017, the European Union announced the regulation EU 2017/2158. It is now the guideline for the accepted level of acrylamide in processed foods. The mitigation measures in this regulation are often considered to be a major concern and a challenge for new

producers. For already existing producers it can even be a problem because their existing technology cannot handle the level of acrylamide in the finished product. The vegetable oil gets bad very quick and to prevent this scenario, they need to change the oil constantly, which is expensive and time consuming.

Oil Quality and Turnover Time

When a producer is frying raw materials in vegetable oil, the oil will be affected by the reactions that takes place in the fryer. The oil will oxidize over time, acrylamide will appear, and the oil eventually gets too bad to use. This results in a need of changing the oil, which is time consuming and expensive. However, if a frying system has a low oil turnover time, with good filtration system and control of the processing temperature, the level of acrylamide level will never be too high since you fry in fresh oil all the time, that is not exposed to too high direct heating.

Plan Your Process After the Raw Material

The main factors to create a product with a low level of acrylamide, is therefore not only to control oil quality and heat, but also to make sure that the product gets to the fryer in a condition were sugars are reduced and small pieces removed. To read more about how you can maintain a high oil quality, reduce sugars before frying and other practical tips when frying potato products, read our article The Ultimate Guide to Fry Potato Chips.

Control the Raw Material for Increased Product Quality and Reduced Acrylamide

Since Potato is a raw material and has different characteristics depending on variety, season, and product handling, we recommend that the producer creates a variety calendar. The reason is to prevent risks involving acrylamide. By planning the production after a specific potato variety, the producer will be prepared for all possible deviations in quality and can always ensure the right characteristics.

The product handling and storing are major challenges since time and temperature of the storing will increase the level of sugars and will subsequently also affect the level of appeared acrylamide in the product. We therefore recommended to have a good relationship with your potato supplier so that you can influence the storing and handling conditions.

Conclusion

The level of acrylamide in processed potato products can be significantly reduced by preventing sugars from entering the fryer and also by having a good oil-management system, making sure that the oil quality is kept high at all times. It is also favorable if the right potato variety is used, depending on season, storing, and handling.

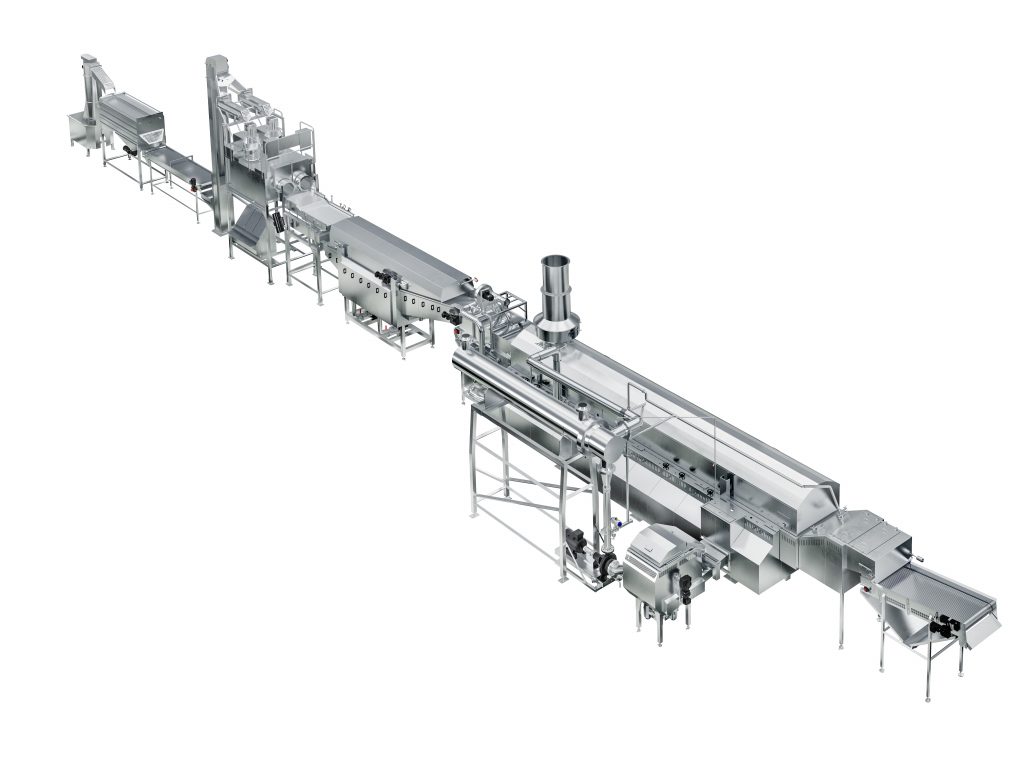

If you are thinking about investing in a Processing Line for a potato product, don´t hesitate to contact us. Are you already a producer and want to know more about how you can reduce the level of acrylamide in your product, you are also more than welcome to contact us. Rosenqvists have over 45 years of experience when it comes to processing raw potatoes and we have a vast knowledge about how you as a producer can live up to existing legislations and mitigation measures.