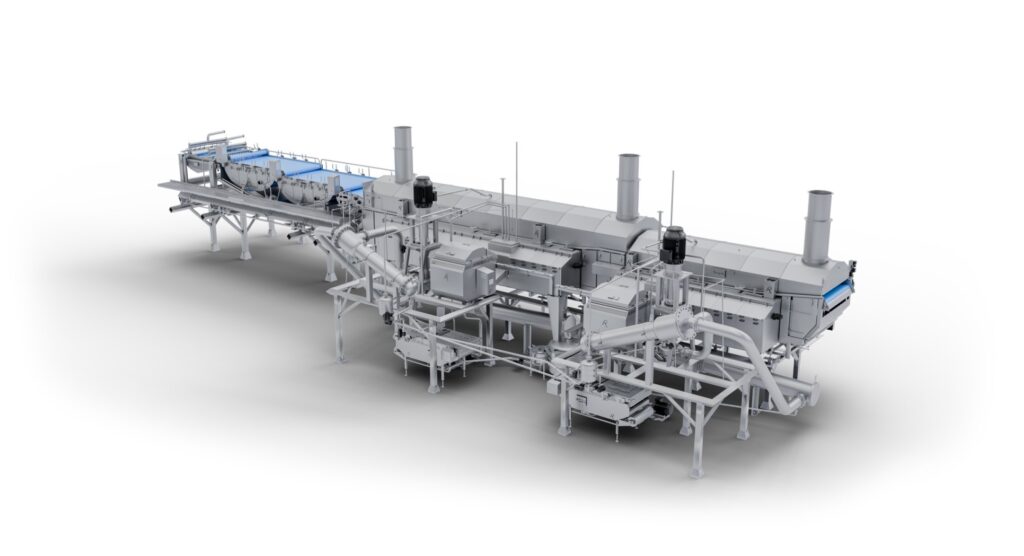

Complete systems for coated fries and other cut potato products

Coated French Fries

The processing steps

Preparation

Aligning infeed shaker: The specially designed infeed shaker ensures that each product is separated before entering the batter applicator.

Coating

Batter mixer: The coating is mixed in the batter mixer, which controls the viscosity and temperature of the batter. The batter is pumped to a circulation tank and from there, it is pumped to the applicator/enrober.

Batter applicator/enrober: The batter applicator handles both thin clear coatings and thick seasoned coatings with high viscosity. The over flow or submerger configurations can be selected to match your product specification. With separated products, we can ensure that each individual product gets an even coverage of batter.

Settling conveyor: During the transfer on the settling conveyor some batter are dripped of and collected for re-usage. During this transfer, the batter have time to settle before entering the first stage fryer.

Feeding

Fryer infeed belt: The infeed belt optimize the feeding of the singulated fries into the first fryer. The nose is adjustable to ensure the correct feeding into the oil.

Frying

Double frying system: The frying takes place in two steps. In Step 1, the coating is set and all products are fried separated. In Step 2, the fries, with a firm coating, will be stacked up as in a conventional fryer.