It was a great experience to see the whole snacks industry gathered again. Two intensive days in Hamburg full of many interesting meetings are behind us. I would like to thank European Snacks Association for organizing the event, I know it has been challenging over the years with pandemic.

Snackex is concentrated on savory snacks and gives us a chance for information and inspiration over just two days. This time, we travel back to Sweden after learning a lot. Fascinating to see the development for snack pellets in terms of new ingredients. Especially encouraging to see interest in developing tailor-made snack pellets for the RoastR, using salt as heating media in processing. For us at Rosenqvists Food Technologies, it gives us an extra boost to see the curiosity for this new technology where you can process snack pellets without oil. Rewarding to be part of the program at the knowledge center where we presented a study comparing fried snack pellets with roasted snack pellets. Thanks to everyone attending our presentation!

Also at the show, we could see the progress made for cutting potato chip slices faster and better. We found out more about the pulse electric field technology. Walking around, we tasted snack flavours from all over the world. My own personal favorite being Chili Verde.

A strong conclusion of our team is the focus on process optimization. With energy and vegetable oil prices being a worry for snack producers it is logical for our clients to do everything they can to save energy, preserve oil quality, re-use water, adjust production schedules and all other factors to optimize the process.

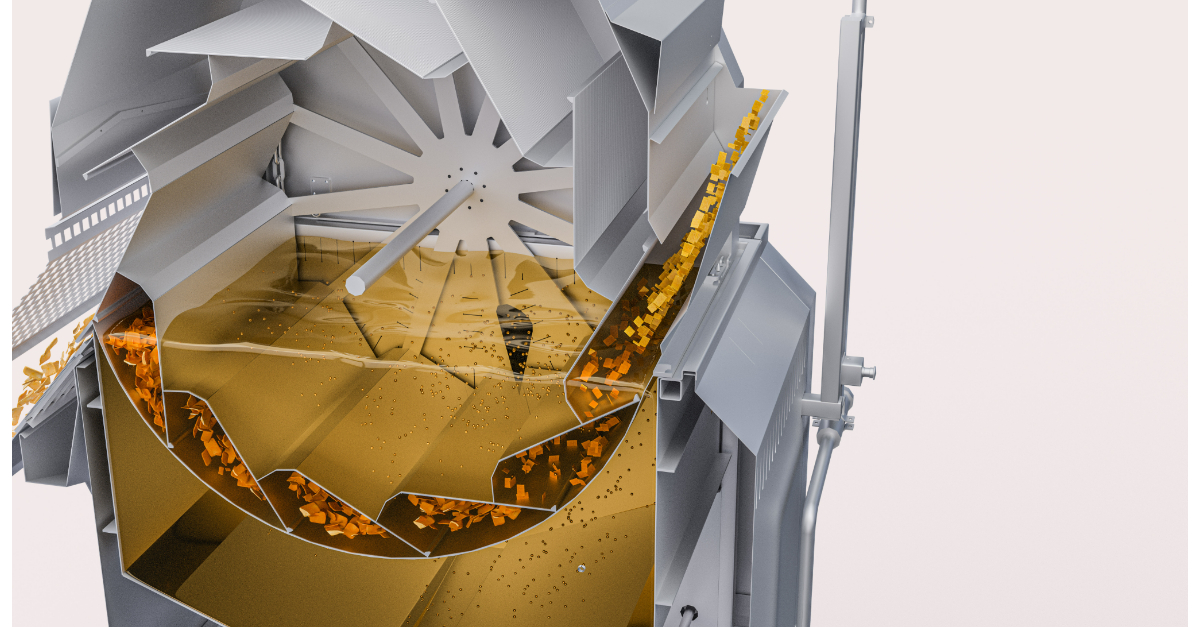

We were delighted to see the interest from visitors taking part of our competition inspired by the multi-zone chips fryer. Guessing the right temperature profile and frying time of a specific potato chip turned out to be quite a challenge. The product sample in the competition was fried over five different zones starting from a 180°C oil inlet temperature. The fryer reduces temperature to 155°C. In the following two zones, the fryer pushes the temperature up to 160°C and in the final zones a gradual decrease down to 152°C. The frying time in the fryer was 225 seconds. In the end it was Lennart Broeer from Lorenz in Germany who made the best guess. We will send him the Garmin Activity Watch as the first price in the competition, congratulations!

Returning to our day jobs improving the possibilities for you as a snack producer, we feel energized and motivated. We will continue to do our best to support you. We look forward to seeing you again in Stockholm, Sweden, where the next Snackex will be organized.

Stefan Björk