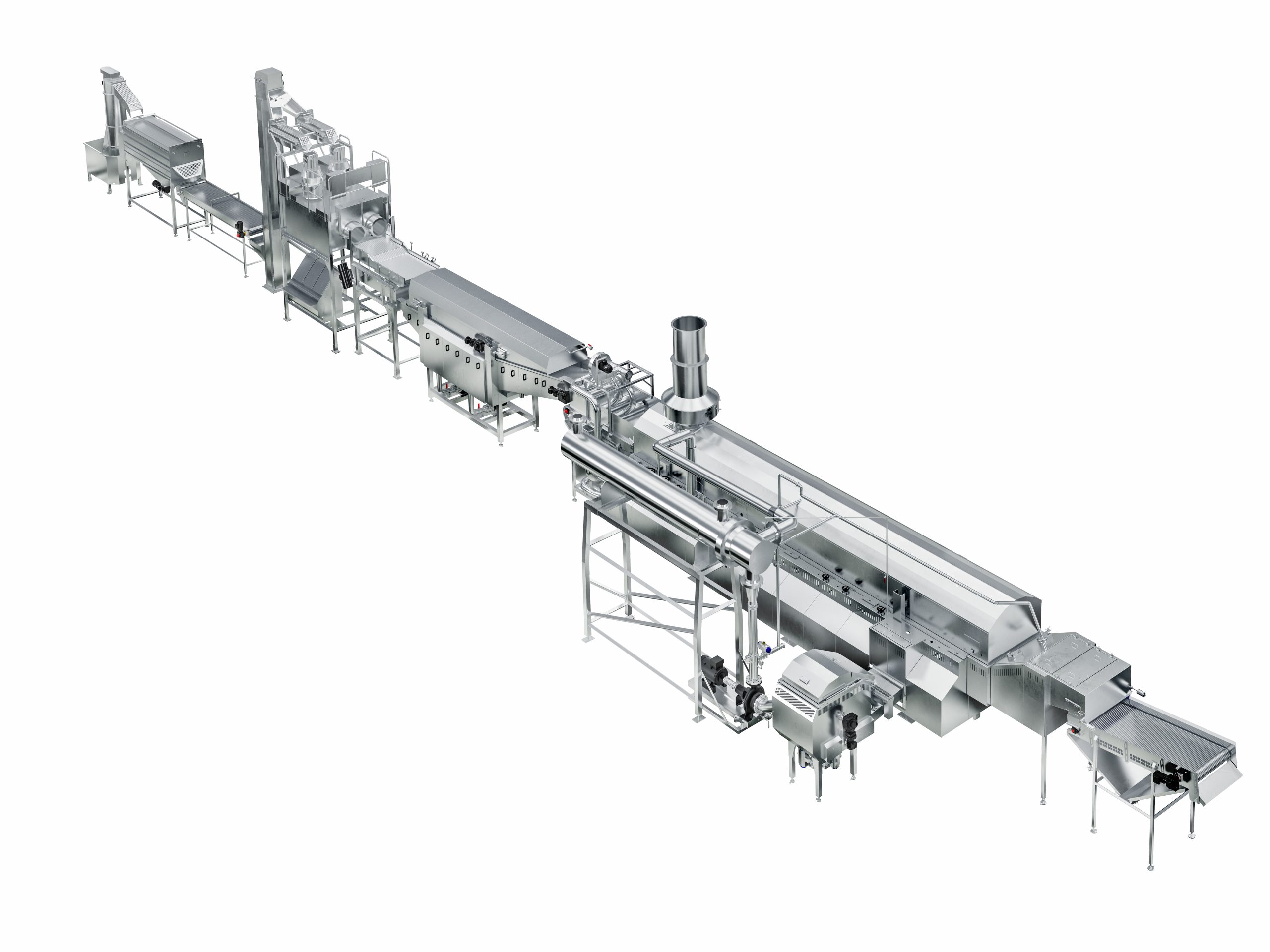

Classic potato chips

The processing steps

Preparation

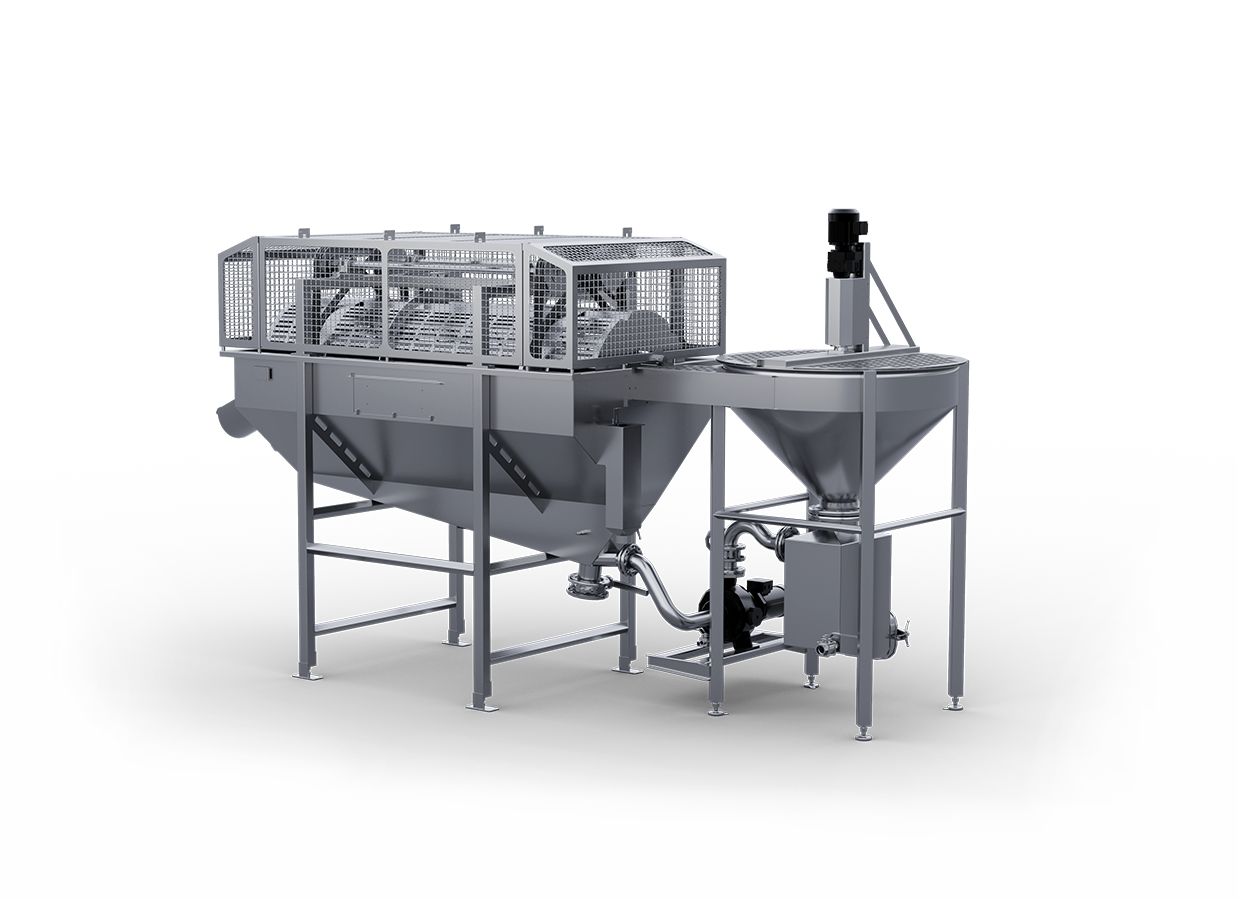

At the potato infeed, we start with creating an even flow of raw potatoes to the process with our Potato Buffer Hopper. It can store from 1-10 tons of raw potatoes and it continuously feeds potatoes to the Auger Destoner, that washes and transports them vertically towards the peeling. If you have more difficult soil conditions, we recommend our Cyclone Destoner with Prewasher. To create an efficient peeling of the raw potato flow, our Continuous Abrasive Peeler de-skins the potatoes using an auger and eight high-speed rollers. As an alternative, our Batch Peeler can be installed. After peeling, the potatoes are passing the Roller Inspection Table and using the Vertical Elevator conveyed to the slicers and Slice Washer.

Cyclone Destoner with Prewasher

Slice Washing

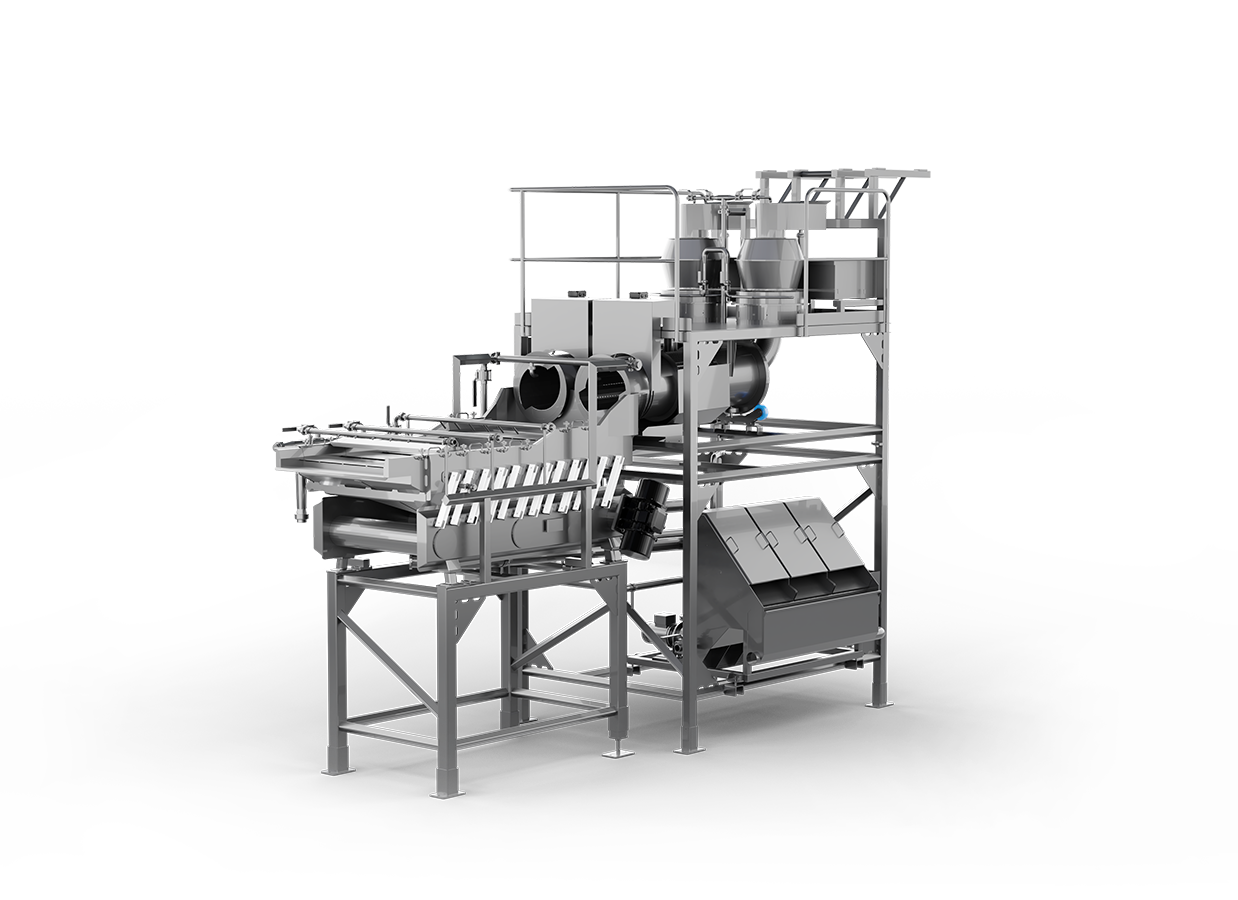

The CC-Feeders separates the potatoes before entering the slicers. The slicers are integrated into our Slice Washer System, a patented three-step washing system for optimal water use. When the potatoes are sliced, free surface starch is released and needs to be washed off. Using three washing steps reduces the water usage to a minimum. The wasing water passes three different waste screens. Rotating drums gently wash each slice and then a vibrating conveyor with an exchangeable screen transports the slices to the blanching step.

Slice Washer System

Blanching

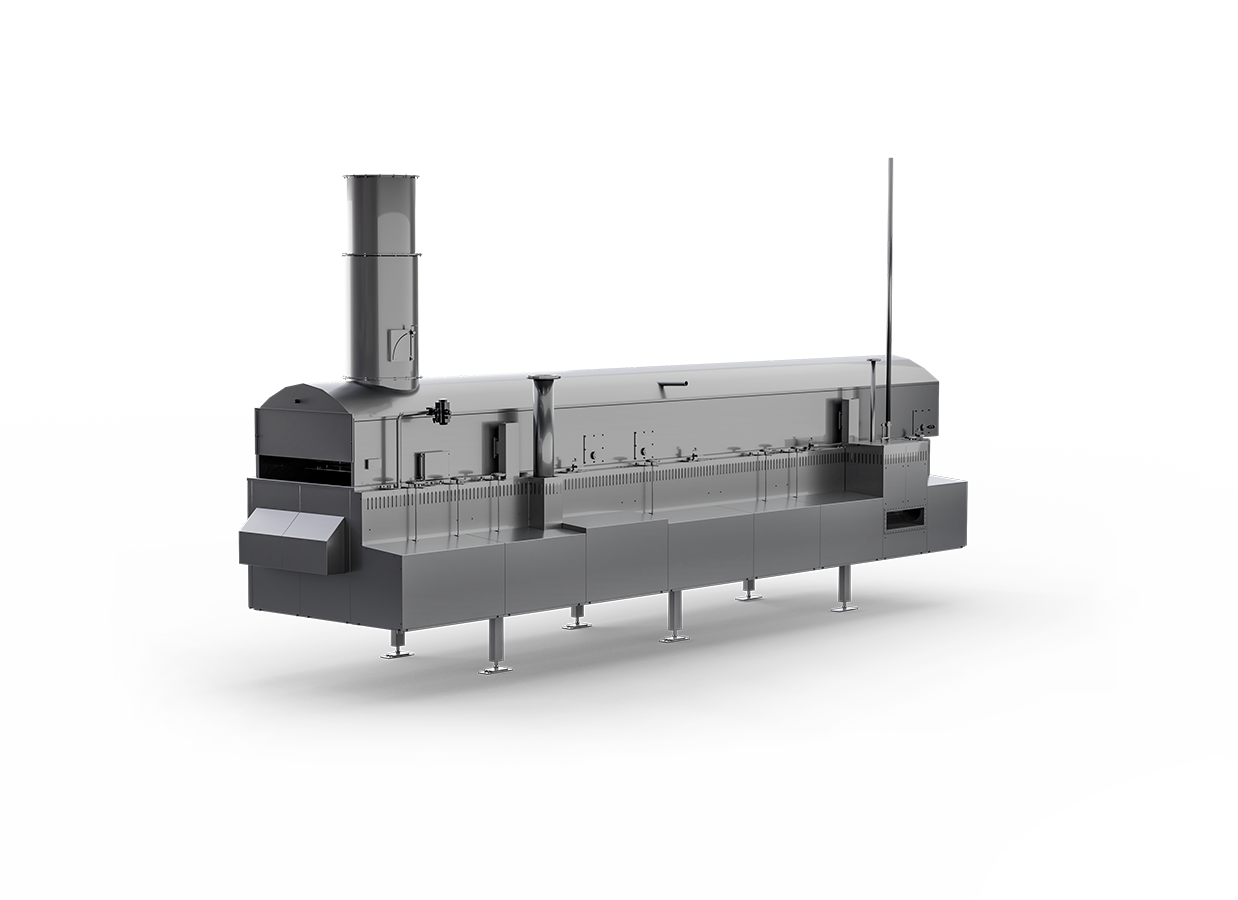

If the sugar content is higher than normal in your potatoes, because of seasonal changes or storing conditions, it is necessary reduce it. By blanching the potato slices in our Multi Turbulent Blancher (MTB), the cell membrane will leak sugar to the surrounding water. The sugar content in the slices will reach a low and acceptable level to avoid browning in the frying step. The patented Flow Injection Side Turbulent (FIST) system ensures that potato slices are separated resulting in an even blanching result. A hood-mounted paddle belt guarantees correct blanching time for each slice. A stainless steel bottom belt gives the possibility to run the MTB blancher without water, if the sugar level in the raw material is low, not requiring blanching.

Multi Turbulent Blancher

Frying

To give the final product the characteristics you desire, we have designed the Multi-Zone Chips Fryer for optimal control of the frying process. The frying system consists of; frying pan, drum oil filter, oil circulation pump and a tube heat exchanger. The Frying pan has several oil in- and outlets, allowing you to control the temperature profile along the fryer. You can therefore customize and design a unique final product with the right crispiness, texture, colour and appearance. The drum oil filter continuously filters every drop of oil every 30 – 45 seconds. The oil pump transfers the vegetable oil into the tube heat exchanger, where the vegetable oil is heated indirectly by thermo oil or steam. To ensure the best frying oil quality and fastest Oil-Turn-Over-Rate, this frying system has the lowest total oil volume on the market.

Multi-Zone Chips Fryer

Download material

Potato chips brochureProduct Sheet - Auger Destoner

Product Sheet - Abrasive Peeler

Product Sheet - Potato Buffer Hopper

Product Sheet - Inspection Table

Product Sheet - Vertical Elevator

Product Sheet - Slice Feeder

Product Sheet - Slice Washing System

Product Sheet - Multi Turbulent Blancher

Product Sheet - Fryer Infeed Belt

Product Sheet - Multi-Zone Chips Frying System

Product Sheet - Continuous Drum Filter

Product Sheet - Inspection Belt

Product Sheet - Defatter